Micro module data center solution

Micro module data center solution

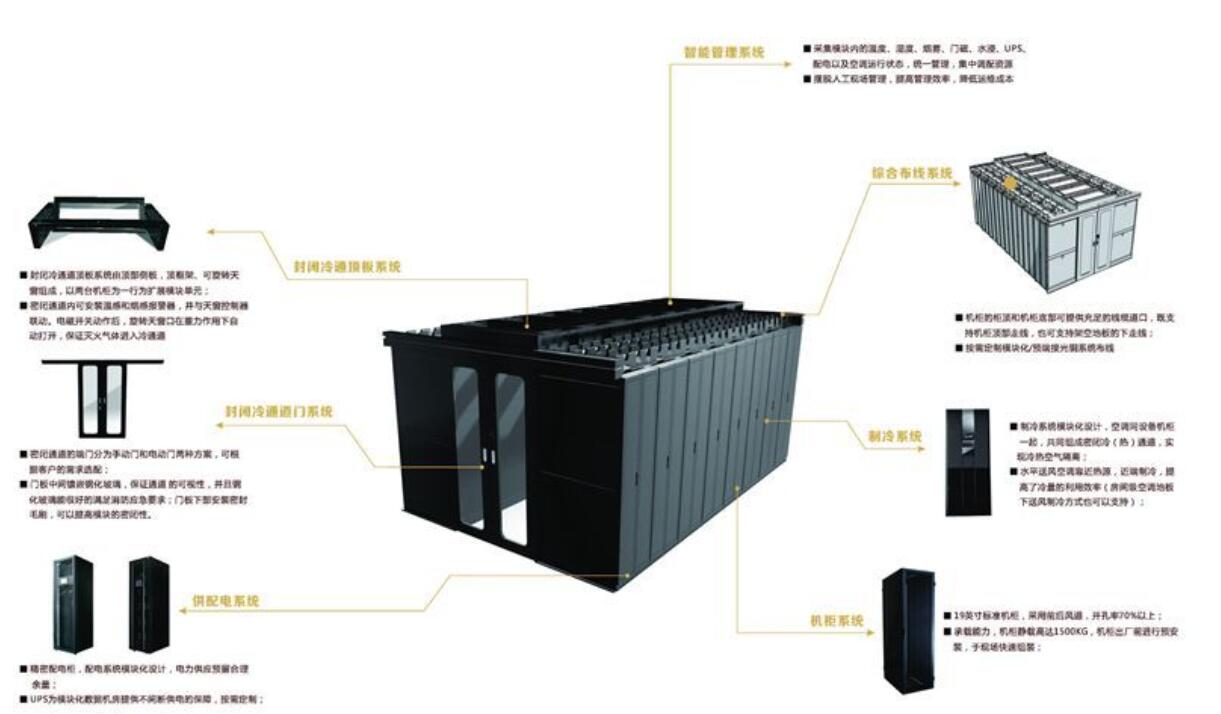

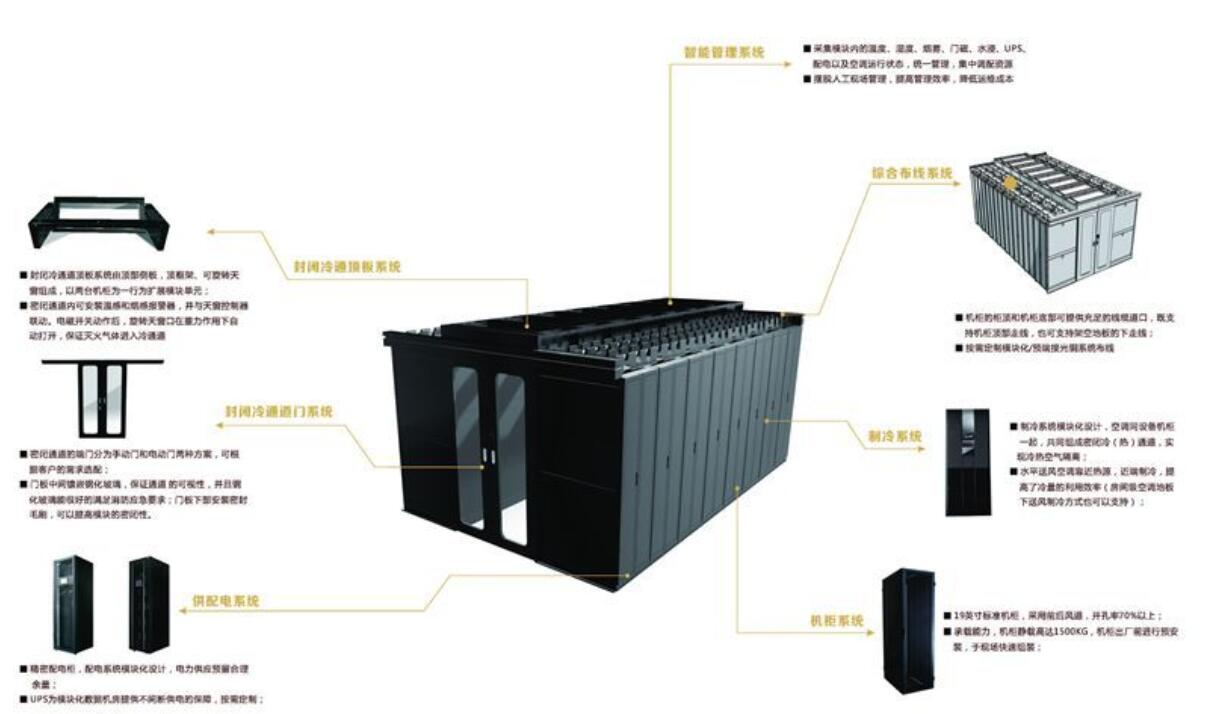

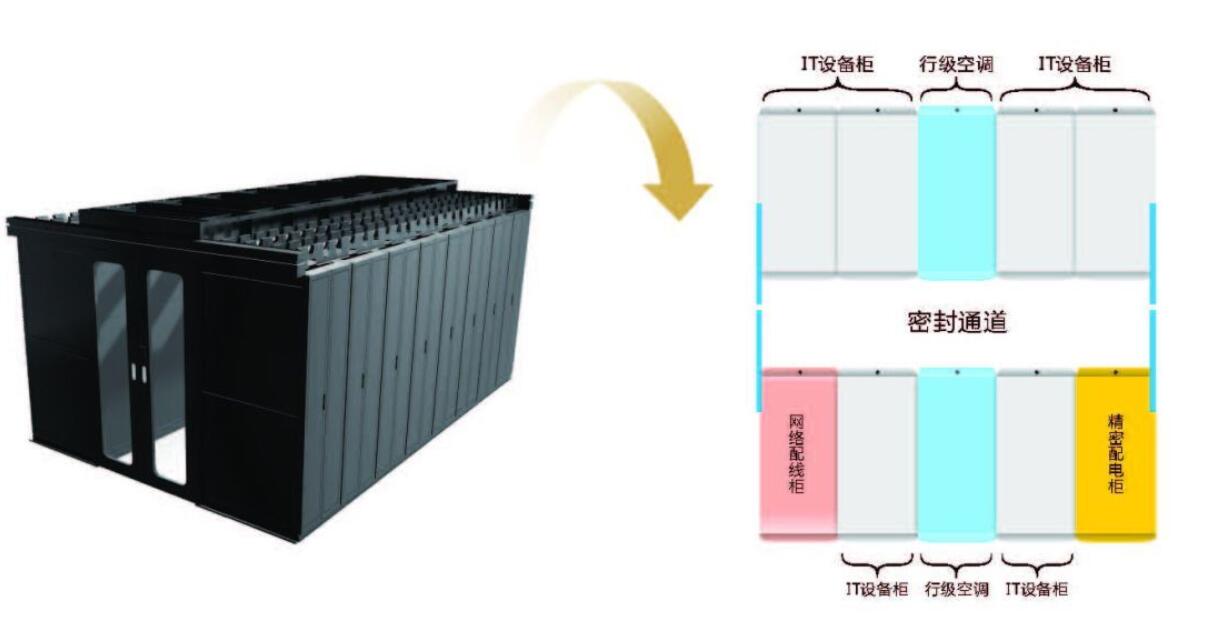

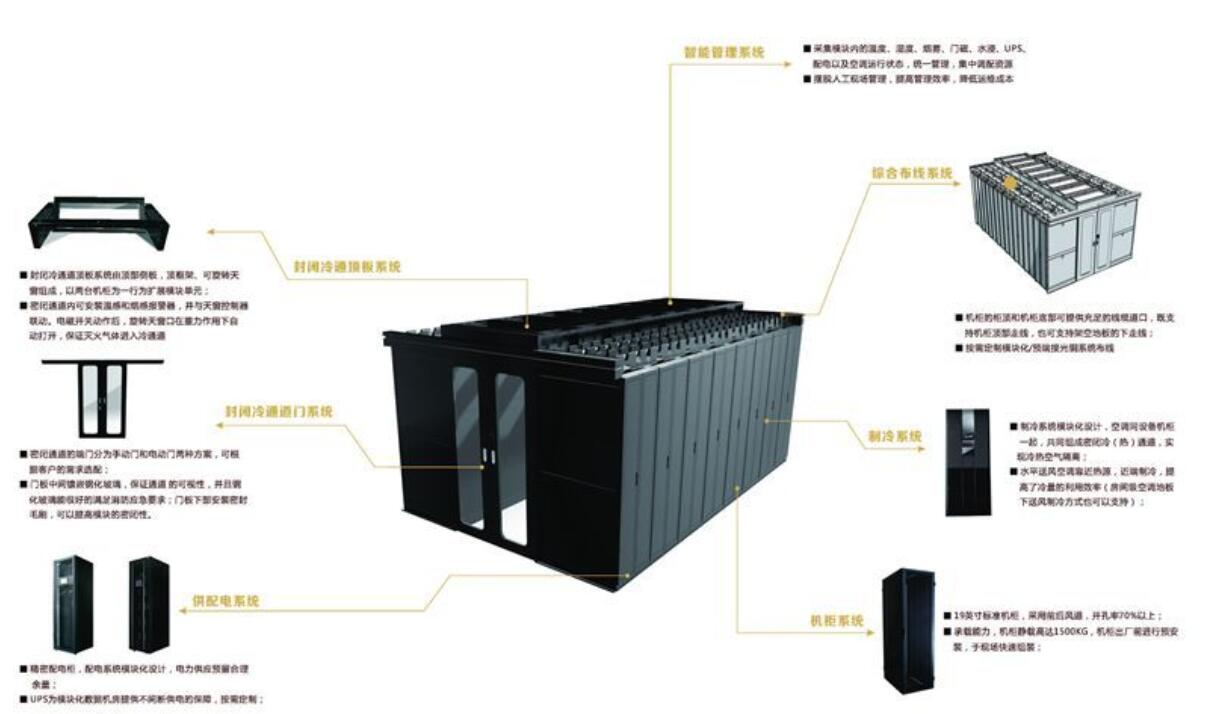

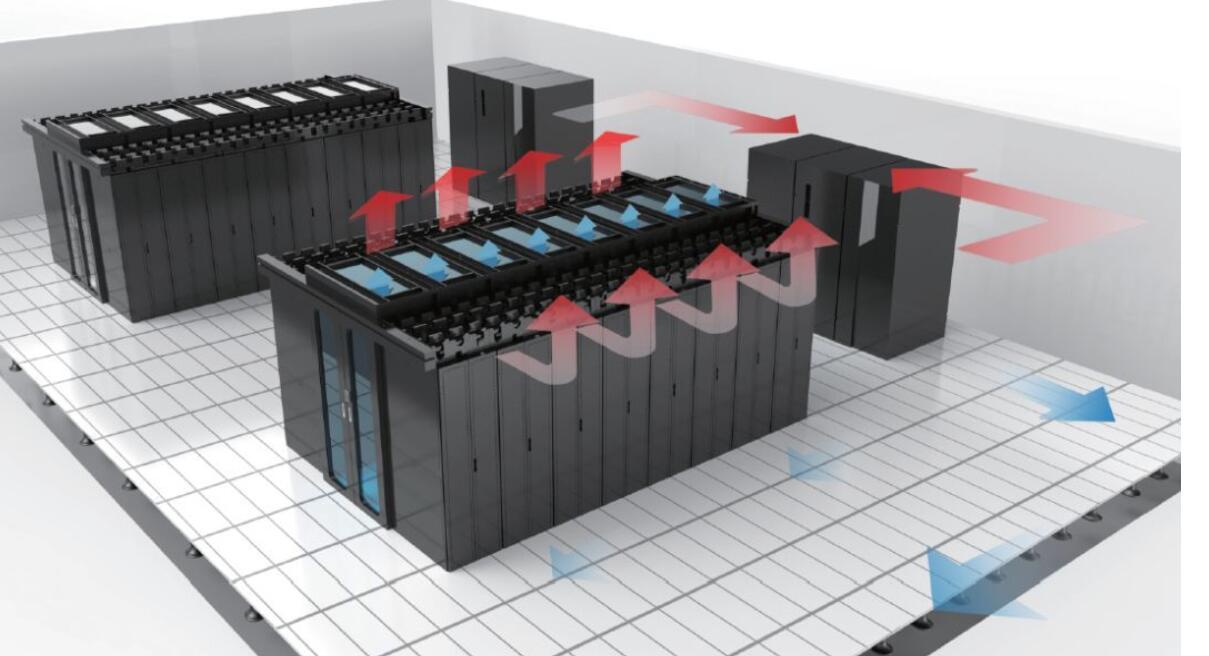

The micro-module data center is designed according to the basic principles of high efficiency, energy saving and optimized management, including cooling modules, power supply and distribution modules, as well as network, wiring, monitoring, fire protection and other modules. The micro-module has an external power supply interface, a cooling interface, a network interface, and an integrated wiring interface reserved through the overhead weak current and strong current slots. The use of in-row air conditioners for cooling achieves a high sensible heat ratio of 100%, effectively reducing the overall humidification and dehumidification energy consumption of the data center. The energy-saving cooling of the data center is realized.

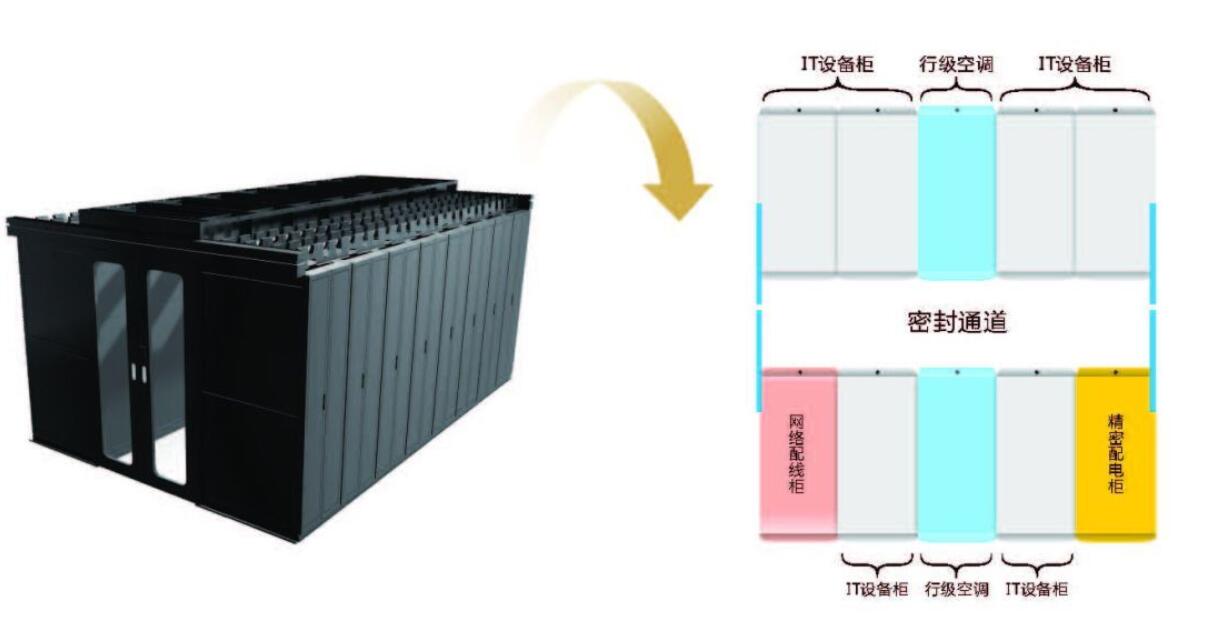

The core system of the micro-module data center is composed of a high-performance cabinet system, a power distribution column head cabinet system, a heat exchanger cooling system, a fire-fighting cold aisle system, an integrated wiring system and an integrated monitoring and management system. The unique cold and hot circulation channel design is adopted, and the exchange of cold and hot air flow in the entire equipment room is completed in the internal closed space, which is not connected with the outside of the equipment room; the aisle corridor is the cold aisle area, and the rear of the cabinet (200mm space) is the hot area. In the passage area, the cooling and heat dissipation of the equipment is realized through the exchange of cold and hot cycles of the switch, which makes the entire refrigeration system more efficient, energy-saving and environmentally friendly.

The integrated management system of the micro-module data center integrates five monitoring and management functions, including power monitoring, environmental monitoring, security monitoring, remote monitoring, and multimedia alarm, so that all physical environment and micro-environmental factors in the entire data center room can be monitored in real time. Monitoring and management, the computer room manager can grasp the operation data of the data center computer room at the first time.

In addition, the entire micro-module data center is also equipped with an intelligent power management system (column head cabinet), a fire linkage roof system, an automatic sliding door system, and an integrated wiring system, which makes the supporting facilities of the entire data center more complete, and various practical application functions are more complete. , provides a complete and reliable computer room comprehensive solution for the installation, use and maintenance of network equipment.

1. Design requirements

index

Require

Computer room construction

Functional Division

Main engine room, auxiliary room (fire control room, power distribution room, monitoring room, UPS room, etc.),

Decoration Materials

Thermal insulation, heat insulation, fire prevention, anti-static, dust-proof, sound-absorbing, moisture-proof, rodent-proof

Raised Floor

Anti-static floor with a thickness of more than 35mm, the clear height from the ground is 400mm-450mm

load bearing

≥500kg/M², the local load-bearing should meet the special requirements of the load-bearing equipment (the floor load-bearing of the air-conditioning equipment and power supply equipment is ≥1000kg/M²)

Water supply and drainage (waterproof)

Any irrelevant water supply and drainage pipes shall not pass through the computer room; the computer room located on the lower floor of the water equipment shall be provided with a waterproof layer on the ceiling, and water leakage sensors and drainage measures shall be provided

environmental conditions

air conditioner

Precision air conditioner for computer room (special air conditioner for constant temperature and humidity computer room)

Temperature and humidity

Summer temperature is 23±2 ℃, winter is 20±2 ℃, relative humidity is between 45% and 65%, no condensation

cleanliness

Tested under static conditions, the number of dust particles greater than or equal to 0.5 μm per liter of air should be less than 18,000 particles per cubic centimeter

Electrical Technology

Supply and distribution system

Two-way power supply, dedicated to the computer room, the quality of the power supply should meet the GB50174-2008 A level

Uninterruptible Power Supply System (UPS)

The load power is less than 65% of the rated power of the single UPS, and the double busbar uninterruptible power supply is realized to ensure that the production equipment works with a delay of more than 1 hour.

Distribution Cabinet

Two-way power supply for all equipment: Two-way UPS power supply provides reliable guarantee for the equipment in the computer room.

Original parts and accessories

It adopts power distribution cabinets and components that meet national standards and qualified quality, overcurrent and overvoltage protection, and the linkage configuration of fire alarm control system, air conditioning system and power distribution cabinet.

wiring

Under-floor power cables should be shielded copper conductors according to the size of the load and laid and welded according to the standard to meet the load requirements; the wiring system should meet the requirements of the national comprehensive wiring standard.

socket

The special socket for the computer room is used, and the mains and UPS power sockets are separated, and the two should have obvious difference marks and meet the load usage requirements.

Three-phase unbalance

Three-phase unbalance should be less than 20%

illumination

The average illuminance of the core area and production area should not be lower than 400 lx, the average illuminance of other areas such as auxiliary areas should not be lower than 300 lx, and the illuminance of backup lighting should not be lower than 40 lx, which is part of normal lighting.

DC ground

The DC grounding resistance should be determined according to the specific requirements of the computer system

AC Protected Ground

Resistance is less than 4Ω

AC ground

AC grounding resistance is less than 4Ω

Lightning protection system

Lightning protection measures shall be taken for the incoming power line in accordance with the national standard GB50343-2004

Lightning protection grounding

Resistance is less than 4Ω

safety ground

Resistance is less than 4Ω

Comprehensive grounding

When four types of grounding, such as AC working grounding, safety protection grounding, DC working grounding and lightning protection grounding, share a set of grounding devices, the grounding resistance is determined according to the minimum value, and the resistance is less than 1Ω.

Engine room power environment monitoring

Power distribution, UPS, precision air conditioning, temperature and humidity, water leakage sensor monitoring, etc.

Anti-rodent pests

Seals, cable casings, and rodent control equipment

2. Design principles

The computer room is the center of all kinds of information. The computer room construction project must ensure that the computer system equipment can achieve long-term, safe and reliable operation, and at the same time provide a beautiful and comfortable working environment for the computer room staff. In order to make the design of the computer room project meet the above requirements, the following points are emphatically considered:

program perfection

The completeness of the design plan Once the computer room project is completed, it is not suitable for staged renovation and transformation.

Decoration aesthetics

The decoration effect of the computer room: to achieve comfortable and pleasant, simple and bright.

Safety and reliability

The design of the computer room emphasizes safety and reliability as the criterion: there is a complete uninterruptible power supply system, a reliable power distribution scheme, a fully functional equipment environment, and effective lightning protection, overvoltage protection and grounding protection measures.

Applicability and convenience

Information technology is changing with each passing day, and technology is being phased out and updated rapidly. In the face of these, what we pursue is to apply first. The design of the complex building and the deployment of the network must be convenient for users to use. No matter how good a complex building and network are in other aspects, if it is inconvenient to use, it is impossible to get the approval of the direct users.

Uniformity and Scalability

The new central data center equipment room and network are not only to meet the current urgent needs, but also to meet the development needs of the next five years or even longer. Therefore, the design should reflect a high degree of scalability, so that it can be gradually expanded according to needs in the future. The scalability of the project: the design of the computer room should have a high scientific and technological content and advanced awareness, and should take into account the space layout, air conditioning and other equipment required in the future. The power capacity can meet the needs of future business development. Build a unified central data center computer room and network environment, build a unified network infrastructure, and achieve a high degree of resource sharing on the premise of ensuring that the applications and security domains of each department are independent. The data of each department in your station can be exchanged and shared dynamically, so that the application system between each department can form an organic whole, and the development and utilization of information resources can be implemented.

Advance and stability

Adopt advanced and mature technology and equipment, and use advanced technology, equipment and materials as much as possible to adapt to high-speed data and needs, so that the entire system can guarantee the advanced nature of technology for a period of time, and has good development potential to adapt to the future Business development and technological upgrading needs. Reliability of equipment room equipment and power supply and distribution devices: All equipment room products that meet national standards or other domestic high-quality standards are used. The technical performance and installation process should comply with national standards to ensure stable system operation.

Flexibility and Scalability

It must have good flexibility and scalability, and be able to expand equipment capacity and improve the number and quality of users according to the needs of continuous and in-depth business development.

Humanize

Emphasize people-oriented, pay attention to the physical and mental protection of staff. In the design of the computer room, special attention is paid to the absolute separation of the human and machine workplaces, etc., and the workplaces for large, high-end and modern equipment are specially divided to meet the special working conditions and working environment requirements required by these equipment, and make corresponding safety protection measures.

standardization

The overall design should be based on international standards and relevant standards promulgated by the state, including various building standards, power and electrical security standards, and computer local area network, wide area network standards, and adhere to the principle of unified norms, so as to lay the foundation for future business development and equipment capacity expansion.

economy

By investing in stages, expanding infrastructure capacity with market changes, avoiding investment risks, reducing investment waste caused by uncertainty, and ensuring optimal investment and continuous development of enterprises. Build a computer room with a high performance-price ratio to maximize the output-input ratio of capital. It can maintain the operation of the system with lower cost and less personnel input, providing high efficiency and high efficiency.

manageability

Due to the complexity of the intelligent computer room system, with the continuous development of business, the task of management will become increasingly onerous. Therefore, in the design, a comprehensive and perfect management and monitoring system must be established. The selected equipment has intelligent and manageable functions. At the same time, advanced and management monitoring system equipment and software are selected to realize advanced centralized management monitoring, real-time monitoring and monitoring of the operating status of the entire system, real-time lighting and voice alarms, and real-time event recording. , so that the fault can be quickly determined and the maintenance work of the management personnel is simplified, thus providing the most powerful guarantee for the safe and reliable operation of the system.

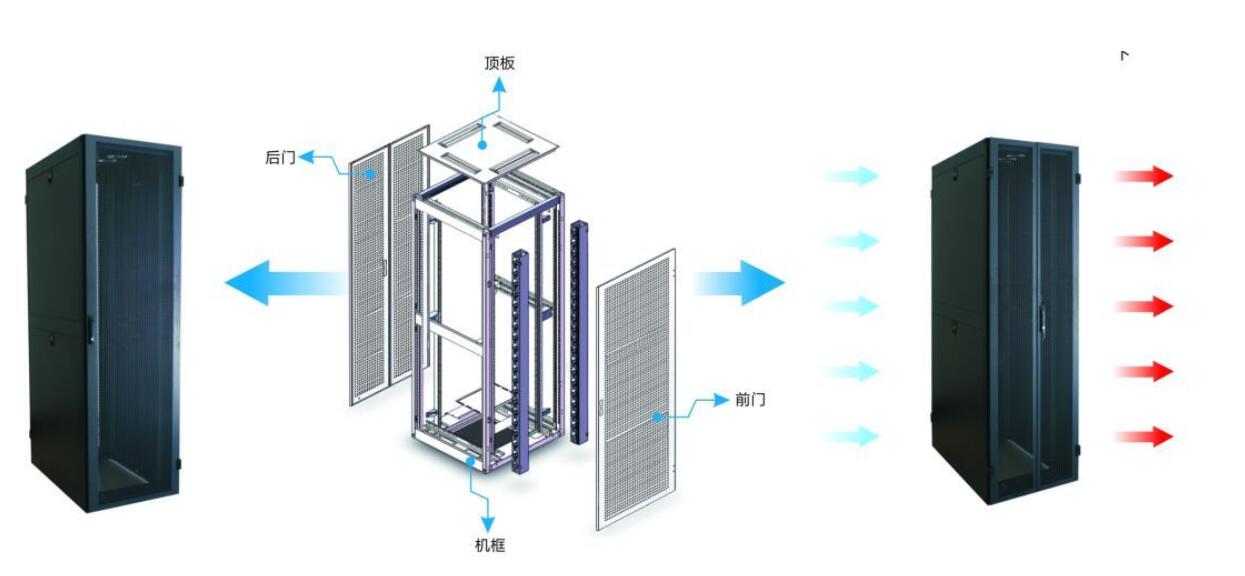

1.2 Cabinet System of Micro Module Data Center Cabinet System

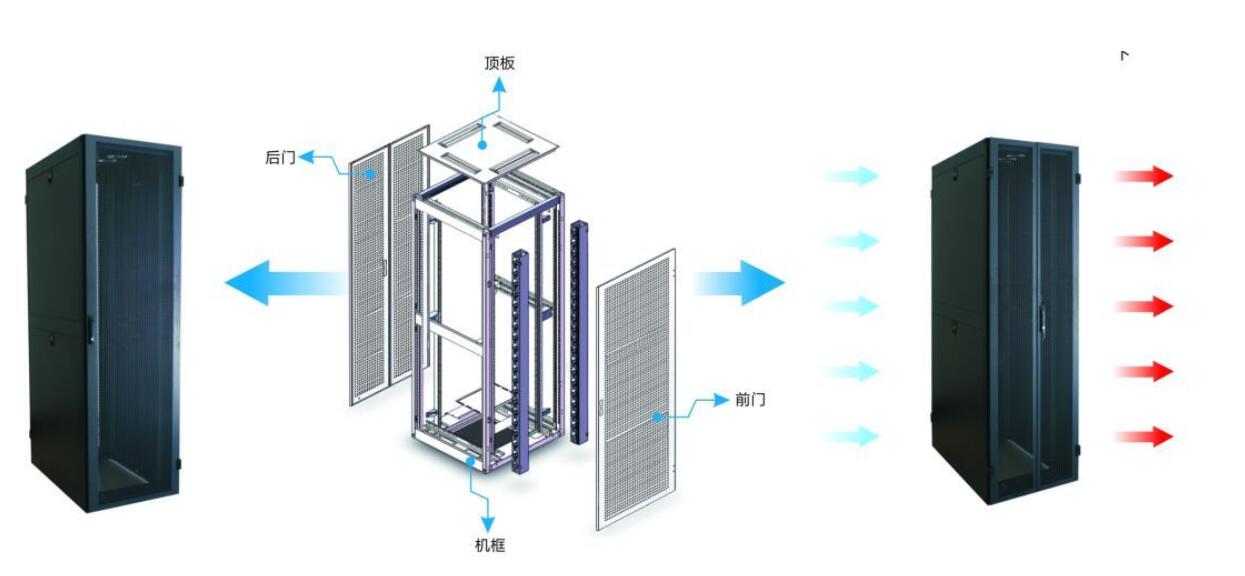

The cabinet is a 19-inch standard high-strength cabinet with a capacity of 42U. Cold-rolled steel plate, the thickness of the steel plate is more than 1.2mm, and the surface is sprayed with plastic; anti-rust, waterproof and anti-corrosion.

1.2 Cabinet System of Micro Module Data Center Cabinet System

The cabinet is a 19-inch standard high-strength cabinet with a capacity of 42U. Cold-rolled steel plate, the thickness of the steel plate is more than 1.2mm, and the surface is sprayed with plastic; anti-rust, waterproof and anti-corrosion.

A hot aisle structure is formed at a position of 200mm at the rear of the cabinet, and the hot aisle area is specially closed. The rear door is a fully enclosed steel plate door, all door seams are filled and sealed with sealing strips, and the side doors are multi-curved. The process is closed, and the hot air is effectively centralized and controlled to ensure that the hot air in the hot aisle does not escape to the space outside the equipment room. The side doors of the modular cabinet are assembled with two left and right side doors. In the open state, after the cabinets are assembled side by side, a closed hot air channel is formed, and the hot air emitted by the servers, CPUs and other equipment at the front of the cabinet is centrally managed in the hot channel area, and the evaporative cooling system is installed side by side. The airflow absorption equipment (with high-density airflow absorption holes) on the side of the intercooling system is used to uniformly recycle the hot airflow.

In order to realize the separation of hot and cold aisles in the data center room and ensure the circulation of cold and hot air flow, in addition to the premise that the overall data center is closed, the most important thing is to deal with the air flow sealing and guiding structure processing of a single modular cabinet; cabinets Except for the 19-inch equipment installation position, the two sides, top and bottom have a unique closed wind shield design (taking into account the function of cable management) to ensure that all cold air can only flow through the server equipment (blow the server to dissipate heat). Control the flow direction of hot and cold air, thus greatly improving the utilization rate of air flow.

1.3 Power supply and distribution system of micro-module data center cabinet system

Precision power distribution cabinet is a power distribution cabinet that comprehensively collects all power supply conditions in the data center room. Provide high-precision measurement data for the terminal energy monitoring system, and reflect the power quality data in real time through the display unit. And upload to the management system through the network. In order to achieve real-time monitoring of the entire power distribution system and effective management of operating status. Help users optimize network data centers, strengthen energy consumption management, improve server rack operation efficiency, and provide reliable protection for all-round green IDC.

As the power distribution of the rack-level and column-head cabinets, it distributes and manages the power supply of the cabinets in the data center, and can accurately monitor the power consumption of each cabinet.

1.4 Heat Exchanger Cooling System of Micro Module Data Center Cabinet System

1. Calculation method of the total heat load of the data center room

l Calculation method of total heat load of main engine room

According to the source of heat in the data center room, the calculation formula used for the total heat load in the data center is as follows:

Qt=Q1+Q2

Where - Qt is the total heat load of the main engine room (kW)

——Q1 indoor equipment load (considering the utilization rate of equipment, Q1 = total equipment power × 0.8)

——Q2 heat load of building environment (=0.12~0.18kW/m2×computer room area, of which 0.12 kW/m2 in the northern region and 0.18 kW/m2 in the southern region)

l Calculation method of heat load of UPS, battery room and power room

The thermal load of the UPS and battery room or power room is calculated by the estimation method, and the calculation formula is as follows:

Q=0.35×S

Where - Q is the total heat load (kW) of the UPS and battery room or power room

——S is the area of UPS and battery room or power room

——The heat load per unit area is taken as 0.35 kW/m2

l Calculation method of heat load in UPS power supply room

The calculation formulas of UPS thermal load and power distribution system thermal load are as follows:

Qups=0.04W1+0.06W2

Where - Qups is the heat load (kW) of the UPS with battery

——W1 is the rated power value of the power system (UPS rated capacity)

——W2 is the total load power of IT equipment

Qp=0.02(W1+W2)

Where - Qp is the heat load of the power distribution system (kW)

2. Selection of precision air conditioning solutions

l Calculation of heat load of main engine room

(1) Heat load of indoor equipment

Calculated based on UPS rated power

UPS rated power KVA

use factor

Equipment load Q1kW

Remark

60

0.8

48

Central computer room

Power calculation based on cabinet design

Cabinet power kW

quantity

use factor

Equipment load Q1 kW

Remark

3

10

0.8

twenty four

Central computer room

(2) Heat load of the building environment

Building area m2

Thermal load factor kW/m2

Building environment heat load Q2 kW

Remark

69

0.18

12.42

Central computer room

(3) The total heat load of the main engine room

Calculated based on UPS rated power

Equipment load Q1kW

Building environment heat load Q2kW

Total heat load QtkW

Remark

48

12.42

60.42

Central computer room

Power calculation based on cabinet design

Equipment load Q1kW

Building environment heat load Q2kW

Total heat load QtkW

Remark

twenty four

12.42

36.42

Central computer room

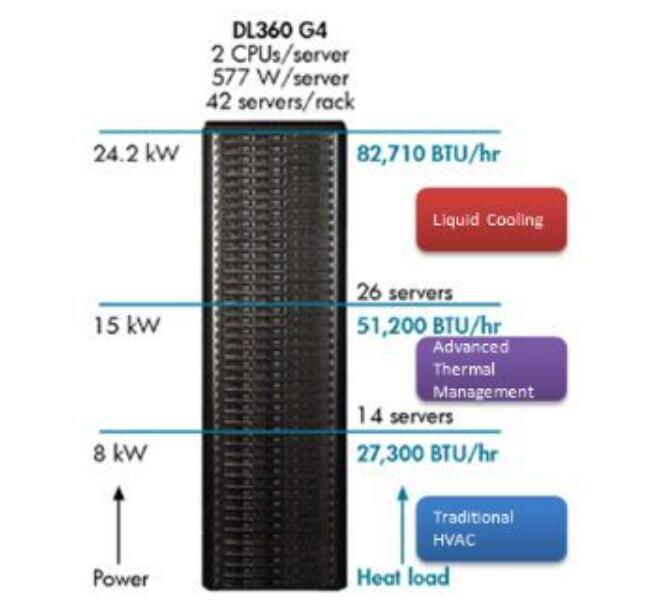

3. Suggestions for model selection analysis of data center computer room

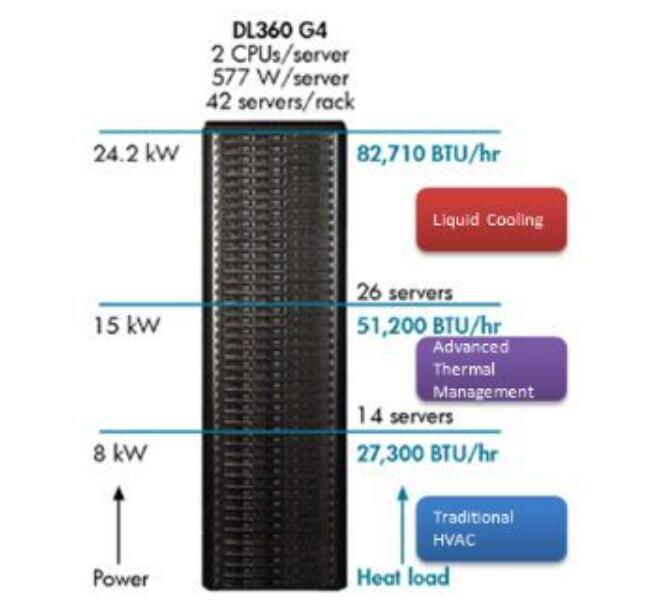

The following figure shows that HP divides the equipment load in the cabinet into 3 grades:

The cabinet load is less than 8KW (5kw in China), which is a small density, and the conventional room-level air-conditioning refrigeration method can meet the demand;

The load of the cabinet is 15KW-5KW, which is medium and small density. It needs to adopt the precise air supply method of row-level air conditioner or room-level air conditioner, and the cooling method of sealing the cold and hot aisles can meet the demand;

When the load of the cabinet is greater than 15KW, due to the high heat density, the row-level heating and cooling aisle sealing and precise air supply must be adopted.

The inter-column cooling system has high reliability, flexibility, dynamic cooling, and has the ability to adapt to the rapid update and change of the computer room load. It can realize the operation of multiple sets of units, and can realize joint control, and a maximum of 32 units can be controlled in a group for unified management.

Row-level cooling: high-performance row-level air conditioners, air-cooled/chilled water options, front air supply and back air return, horizontal air supply distance is only 2-6m, not limited to air ducts and perforated floors, air supply efficiency Greatly improved, perfectly matching high-density + closed hot and cold aisle scenarios, greatly reducing PUE, and solving local hotspot problems;

For example, the number of existing cabinets is 22, and the power of a single cabinet is 3KW. Considering that the row-level precision air conditioner is used for cooling, the cooling method of this solution has very little loss. It does not need to be calculated according to the traditional algorithm, and can be calculated as follows:

Total cooling capacity Q = equipment load + redundant load (10-20% of equipment load)

=22KW×3×1.1 =72.6KW

Because the computer room of this scheme is designed in accordance with the national class B computer room standard, all the refrigeration equipment needs to be configured with N+X redundancy, that is, the refrigeration equipment needs to have fault-tolerant redundancy. In this scheme, we use 4 row-level precision air conditioners. The cooling capacity of the air conditioner is 25.5KW, and the sensible heat ratio is 100%. 3+1 redundant configuration, the cooling capacity of 3 air conditioners is 76.5KW, which can meet the cooling demand of the computer room. Another air conditioner is used as a redundant configuration, and 4 air conditioners are used for cooling rotation to provide the service life of precision air conditioners.

Choice of cooling method

Conventional precision air conditioners have four cooling methods: air cooling, water cooling, chilled water cooling, and ethylene glycol cooling.

According to the computer room, two kinds of precision air-conditioning units, air-cooled and chilled-water-cooled, are mainly used. The characteristics of air-cooled and refrigerated water-cooled units are now compared in order to provide the optimal solution.

Principles of air-cooled and chilled water-cooled air conditioners

1.5 Cold aisle system of micro-module data center cabinet system

Cold aisle sealing components mainly include top sealing plate and aisle sliding door, single-row sealing components and double-row sealing components are provided according to the site environment

Each aisle top plate has the same width as the cabinet and is fixed to the cabinets on both sides. The material is flame-retardant plexiglass + sealing strip + metal frame, the thickness of flame-retardant plexiglass is 4mm; the color is fully transparent, and the metal frame is black matt fine sand grain; it does not affect the lighting, and there is no need to add lighting in the channel.

In order to better solve the hidden dangers of fire protection in the data center, we designed the channel roof that works in conjunction with the fire protection system. The 220V commercial power is transformed into 12V DC after the power adapter is converted to supply power to the magnetic lock. The magnetic lock keeps the flip plate and the outer frame closed when the power is on, so that the channel can be sealed; when the fire protection system sends out a fire alarm signal, The circuit breaker receives the signal and turns off the switch. At this time, the power of the magnetic lock disappears, and the top plate turns around the rotating shaft under the action of gravity. It can be opened instantaneously within 0.5 seconds, and the opening area is not less than 30% of the total area of the top partition plate. To achieve the required channel for fire-fighting gas discharge, open the fire-fighting gas to achieve the purpose of fire extinguishing. After the top partition is opened, it will not hinder the normal operation of other equipment components in the data center and the passage of personnel in the cold aisle.

The entrances at both ends of the aisle of the data center are closed with sliding doors, the material is tempered glass with metal frame, and the thickness of tempered glass is not less than 5mm; the inside of the aisle can be clearly seen, the door is double-layered, and the handle is installed, and the door opening method is hinge + double door + Smart locks can be opened both inside and outside the channel;

All-aluminum alloy guide rail, side door structure design, motor drive mode

Features:

*Silent automatic door

The design of the drive device is unique and ingenious, breaking through the transmission mode of traditional automatic doors, with compact structure and good performance.

Depend on. Eliminate noise pollution and ensure the safety and comfort of the environment in the data center.

* Anti-pinch safety feature

Special humanized anti-pinch function design, can return when blocked, greatly improve safety performance, avoid safety

All accident hazards.

* Automatic power on function after power failure

It is especially important to set the function of automatic opening after power failure.

* Multiple styles of access control options

You can choose password lock, fingerprint, credit card, induction, remote control, manual access control.

* Humanized action adjustment

The opening/closing speed, buffer distance, buffer speed, and opening time of the moving door can be adjusted according to actual needs.

Adjust the action parameters from time to time.

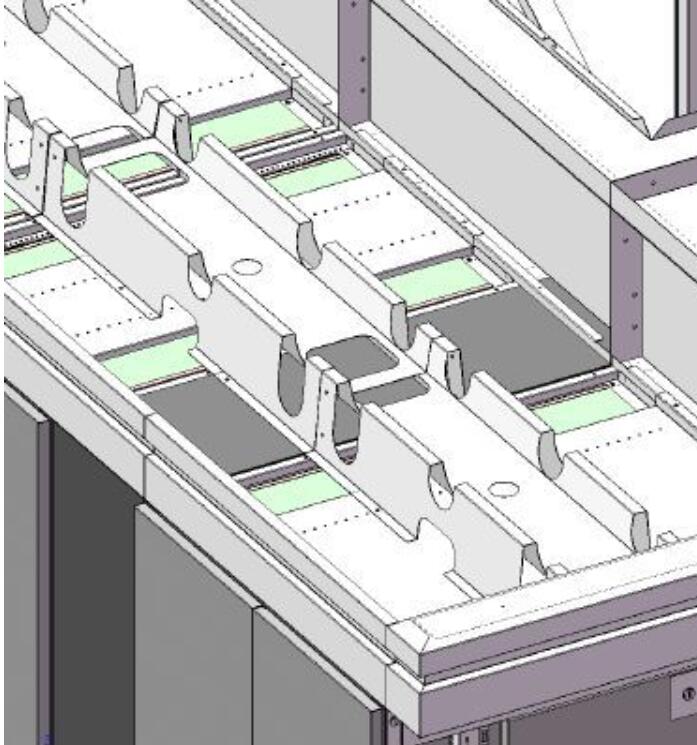

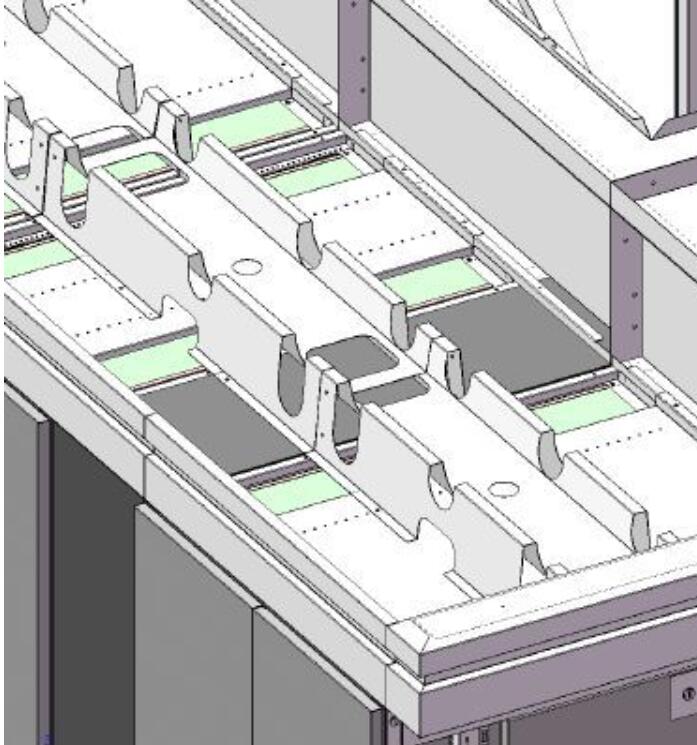

1.6 Integrated wiring system of micro-module data center cabinet system

The data center is designed with horizontal and vertical bidirectional multi-functional wiring troughs on the top of the cabinet, and supports the wiring method of separating strong and weak electricity, providing a more convenient and simple wiring solution for each household. As shown in the figure, the cable trough is installed horizontally on the top plate of the cabinet, and can be adjusted at any position in the front and rear. When multiple groups of cabinets are combined, the cable trough will also form a corresponding cable trough group to realize the mutual wiring between the cabinets.

The data center is designed with horizontal and vertical bidirectional multi-functional wiring troughs on the top of the cabinet, and supports the wiring method of separating strong and weak electricity, providing a more convenient and simple wiring solution for each household. As shown in the figure, the cable trough is installed horizontally on the top plate of the cabinet, and can be adjusted at any position in the front and rear. When multiple groups of cabinets are combined, the cable trough will also form a corresponding cable trough group to realize the mutual wiring between the cabinets.

Main distribution area (MDA): place routers, backbone cables, LAN/SAN switches, PBX program-controlled switches, and patch panels;

Horizontal distribution area (HDA): place LAN/SAN/KVM switches and distribution frames;

Regional distribution area (ZDA): place the junction box/integration point in the intermediate connection area between HAD and EDA; (construction is not considered in this scheme)

Equipment Distribution Area (EDA): Place racks/cabinets/equipment, outlet boxes.

In addition, the computer room/host room is directly related to the access room (ER), which houses the access equipment for network operation.

The main wiring area is considered to be the core of the data center, and is generally set in the center of the computer room or near the core, so as to minimize the distance between the horizontal wiring areas.

At the beginning of the design, enough space should be reserved in the main wiring area. It is generally recommended to reserve at least 50% of the space for future upgrades. Avoid the trouble of insufficient space when upgrading in the future. It is recommended that the optical/copper patch panels be placed in different cabinets. The backbone system of the data center includes the main distribution area (MDA) to the horizontal distribution area (HDA), the backbone wiring system between multiple MDAs.

The backbone system is recommended to use a combination of single/multimode fiber optic cable and copper twisted pair cabling to back up each other.

Backbone fiber optic cable: supports the current mainstream 10G Ethernet, and considers future-oriented 40G/100G applications, using laser-optimized OM3/OM4 multi-mode fiber optic cable or OS2 low-water peak single-mode fiber optic cable. Adopt LC or high density MTP/MPO interface.

Backbone copper cable: As the backbone system connecting the core switching network, the aggregation switching network and the access switching network, it is recommended to use a 6A shielding system to support network transmission.

In order to complete the rapid deployment of the optical cable trunk from MDA to HDA, it is recommended to use a pre-terminated optical system to reduce the space occupation as much as possible.

The 6A shielding system of the integrated wiring of the data center is mainly composed of a 6A 4-pair shielded cable, a 6A shielded jumper and a 6A shielded distribution frame. Applied to the transmission requirements of 10 Gigabit and above, its performance indicators exceed the 500MHz requirements of ANSI/TIA 568-C.2, while providing significant headroom. With SHIP's high-performance Category 6A connection hardware, it provides users with more optimized transmission performance support, greatly reduces the loss of near-end crosstalk (NEXT) and far-end crosstalk (ANEXT), and meets the data transmission requirements of data centers. The jacket material is flame retardant (CMR) or low smoke zero halogen (LSZH) to ensure application safety.

New and expanded high-performance MPO or high-density pre-terminated optical system solution, consisting of high-quality optical cables and components, ensures forward-looking support for important data center links, including 10Gb/s, future 40Gb /s and 100Gb/s applications. The solution can be installed with a simple pull and plug operation, which is much faster than traditional field-terminated fiber connections.

The pre-terminated system consists of MPO pre-terminated optical cable, MPO pre-terminated module, MPO pre-terminated optical fiber distribution frame, etc. The pre-terminated fiber optic cable is in increments of 12 cores, using 50/125μm 10 Gigabit (OM3) multi-mode fiber or OS2 low-water peak single-mode fiber, plug end face B-type structure, and MPO-MPO or MPO-LC/ SC has a variety of interface methods. According to customer needs, it provides various types of pre-terminated optical cables with different core counts, different lengths, different end face structures and different interface methods to achieve high-performance and high-density fiber system connections.

MPO pre-terminated modules feature small cross-section, light weight, and easy installation, with a convenient 12-fiber MPO connector at the rear of each module, and up to 12 or 24-fiber LC/SC connections at the front head.

Each equipment cabinet is installed with a 24-port distribution frame, a 12-core pre-terminated optical cable, and a 12-port optical distribution. The information points in each cabinet are converged to the network column head cabinet of the channel.

The integrated wiring copper cable system needs to use the 6A shielding system, the optical fiber system uses the 10 Gigabit multimode optical cable, and the optical fiber link adopts the pre-terminated technology.

Please refer to the configuration list for the required products

1.7 Integrated monitoring and management system of micro-module data center cabinet system

The monitoring and management system is a management service platform for centralized monitoring systems such as computer room power, environmental security, server system resources, and network resources.

Multifunctional remote centralized monitoring system designed for manned substation ; Fire controllers, smoke detectors, temperature detectors, access control, video, burglar alarm, host and other equipment.

4. Power monitoring system

1). Distribution monitoring

Effectively compatible with PDM (power management system) through the remote RS485 communication interface, the collected parameters can be transmitted to the computer room monitoring system, and the computer room management personnel can monitor the running status of the equipment in real time. It can monitor the voltage, current, frequency, total power, active power, reactive power, power factor, load percentage, electricity (measured monthly according to customer needs), historical trend graph and other parameters of the main branch.

The various parameters of these main and sub-circuits are displayed on the LCD screen. It is convenient to maintain and handle system failures. For various abnormal situations of the mains, such as mains power failure, unstable power supply frequency, high single-phase load, etc., the system will immediately pop up the corresponding alarm window, and at the same time, it will send out multimedia voice, telephone voice dialing, mobile phone text messages, voice Inform the computer room management personnel by means of light and other external alarms.

2). UPS monitoring

Real-time monitoring of UPS input and output voltage, current, frequency, power, battery capacity, voltage, temperature and other parameters, rectifier, inverter, battery, bypass, load and other components of the working status and parameters.

The upper and lower thresholds can be set for the monitored parameters. Once the mains exceeds the limit alarm, the parameters that have alarmed at the corresponding position will be displayed in red, and the alarm events will be recorded and stored, and there will be corresponding processing prompts. And the first time to send multimedia voice, telephone voice dialing, mobile phone text messages, E-Mail, sound and light and other external alarms.

5. Environmental monitoring system

1). Temperature and humidity monitoring

By installing temperature and humidity sensors with liquid crystal display in important parts of the equipment room to monitor the ambient temperature and humidity, the current temperature and humidity values can be seen in real time on the surface of the temperature and humidity sensor, and the RS485 intelligent interface and protocol conversion of the temperature and humidity sensor can also be used. The device uses TCP/IP to connect the signal to the serial port of the monitoring server, and the monitoring platform software performs real-time monitoring of temperature and humidity.

The system can set over-limit thresholds (upper and lower limits) for temperature and humidity parameters. Once an over-limit alarm occurs for temperature and humidity, the alarmed parameter will turn red and flash, and an alarm event will be recorded and stored. Corresponding processing prompts, and the first time to send multimedia voice, telephone voice dialing, mobile phone text messages, E-Mail, sound and light and other external alarms.

2). Water leakage monitoring

Since there are water inlet and outlet pipes of the cooling equipment between columns in the equipment room, in order to prevent the potential safety hazard of liquid leakage and ensure the requirement of early detection and timely treatment, it is designed to install a water leakage sensing rope (select the positioning type or regional type) and water leakage detection in the place where there is an air conditioner in the equipment room. equipment to ensure the stable operation of the equipment in the computer room.

Real-time monitoring of water leakage in the computer room, once water leakage occurs (location of water leakage can display the specific water leakage position, accurate to meters), the parameters of the alarm in the corresponding position will turn red and displayed, and alarm events will be recorded and stored, and there will be corresponding processing prompts , and the first time to send multimedia voice, telephone voice dialing, mobile phone text messages, E-Mail, sound and light and other external alarms.

3). Monitoring of inter-column cooling system

Real-time monitoring of the running status of the inter-column refrigeration system, including indoor temperature, indoor humidity, compressor status, fan running status, power on/off status, dehumidification, heating, cooling, etc., as well as fault status, etc.

The upper and lower limit thresholds can be set for the monitored parameters. Once the mains exceeds the limit alarm, the parameters that have alarmed at the corresponding position will be displayed in red, and the alarm events will be recorded and stored, and there will be corresponding processing prompts. And the first time to send multimedia voice, telephone voice dialing, mobile phone text messages, E-Mail, sound and light and other external alarms.

6. Security monitoring system

1). Smoke monitoring

By setting the smoke sensor in the important area of the computer room, when a fire occurs, the smoke sensor transmits the alarm signal to the regional information acquisition module controller, and then transmits the information to the monitoring platform through TCP/IP, and the monitoring platform software performs real-time monitoring of smoke.

Real-time monitoring of fire alarm signals in the computer room; once an alarm occurs, an alarm event will be generated for recording and storage with corresponding processing prompts, and multimedia voice, telephone voice dialing, mobile phone text messages, E-mail, sound and light, etc. will be sent to the outside world at the first time. Call the police.

2). Video image monitoring

Monitor the real situation in the computer room of the entire data center through the video screen equipment, and monitor any situation in the computer room in real time and in an all-round way.

A camera is installed in the computer room, which is monitored and controlled by a computer. When someone enters the computer room, the light is automatically turned on, the camera is activated, the computer automatically pops up the live image screen, and the hard disk recording is started, or the computer is armed to start the recording.

7. Remote monitoring system

Each monitoring and monitoring device feeds back the real-time information of its monitoring system to the designated PDA or monitoring workstation through the server management platform, so that the administrator can keep abreast of the operation of the computer room at any time.

8. Multimedia alarm

Support multimedia on-site voice accurate alarm, short message alarm, telephone voice alarm, email alarm and other methods.

Each monitoring object can set its own alarm method according to its needs, with precise positioning ability; it supports hierarchical time-sharing alarm, which can be set according to needs;

Latest News

Contact Us

Name: Lisa Zhou

Tel: /WhatsApp 86 198 0409 1024

E-mail: sales@frontierstech.com

Skype: 0086 19804091024

MSN: 0086 19804091024

QQ: 0086 19804091024

WeChat: 0086 19804091024

Whatsapp: 0086 19804091024

Add: No.2568 Gudai Road, Minhang District,Shanghai,China

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online